Nicola Mining announces test results from Magnetite Recovery

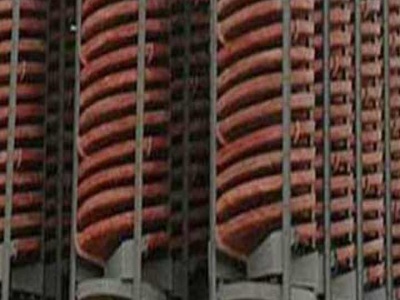

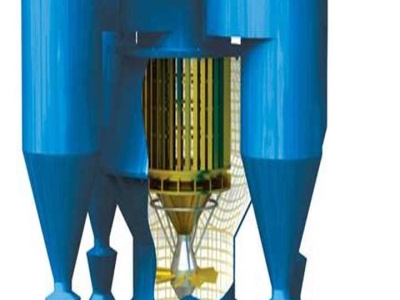

Nicola Mining Inc announced the results of a preliminary metallurgical testing program and the significance of a coppermagnetite grade equivalent at its whollyowned New Craigmont Project ...