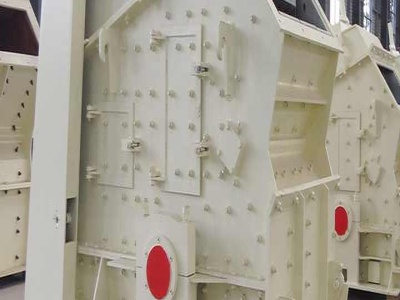

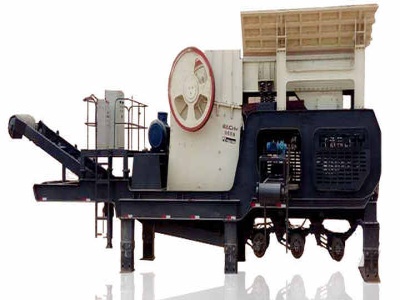

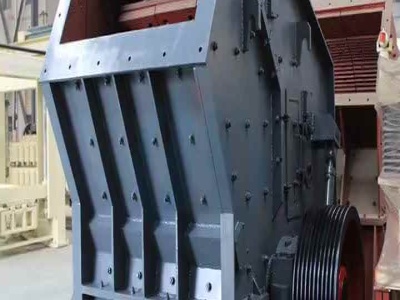

aggregate rock production process in india

Jul 27, 2016· Aggregates for Concrete GreenSpec. For a good concrete mix, aggregates need to be clean, hard, strong particles free of The process of extraction from rock quarries usually involves explosives to shift the rock The output is a range of sizes of rock produced to specified sizes. Sand and aggregate washing in India CDE Global