MSDS: Sand and Gravel Material Safety Data Sheet

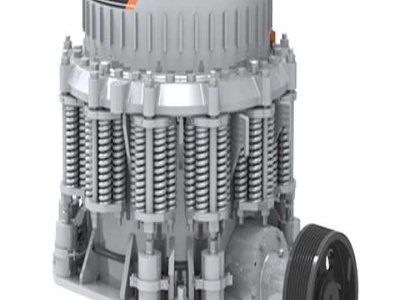

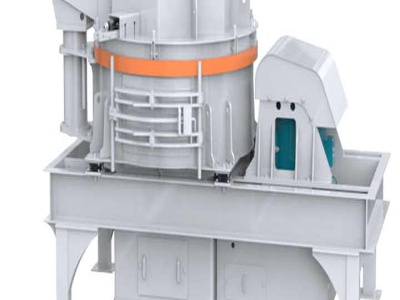

contains sand or gravel. Sand or gravel can buildup or adhere to the walls of a confined space. The sand or gravel can release, collapse or fall unexpectedly. Usage: This product is NOT to be used for abrasive blasting. Cutting, crushing or grinding hardened cement, concrete or other crystalline silica